Emergency Service? Call Our 24/7 Line (800) 462-3369

Our Boiler Deaerator Services

ISB recommends facilities utilize deaerators for consistency, reliability, and lower operating

cost over the life of your system. Our team has the tools and experience necessary to both

maintain existing deaerator systems and installing new deaerator systems for boiler to capture their benefits.

- Servicing spray or

tray deaerator types - Non-destructive

examination of vessels - Maintain existing or

fabricate new solutions

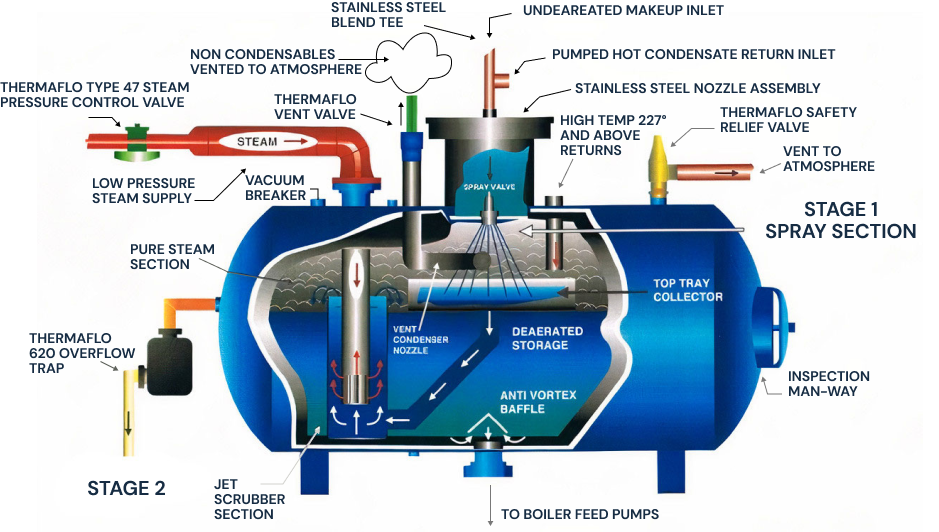

Spray Type Deaerator System For Boiler

ISB Inspection & Scope Of Boiler Deaerator System Services:

From maintaining existing systems to designing and fabricating new solutions, customers will have peace of mind knowing we will expertly manage the job from start to finish. ISB provides all the necessary labor, materials, and equipment for a complete non-destructive examination of vessels within your facility. All deaerators and tank, including those vessels designed as ASME or designated as non-ASME constructed, should be periodically inspected to ensure proper operation of equipment performance and safety of plant personnel.

ISB Inspection & Scope Of Boiler Deaerator And Tank Services:

Boiler Deaerator And Tank System pre-inspection requirements:

Review data reports

Perform Lock Out Tag Out

Visual examination of internal

and external welds

Cleanliness of the vessel interior is important to the inspection process. Deposits or scaling of any kind have the potential for masking discontinuities and rendering the inspection process and results flawed

Identify any indications of corrosion, erosion, FAC, scale deposits, pitting, material thinning and weld cracking; noting location of any mechanical deficiencies and paying close attention at the intersections of circumferential and longitudinal seams.

Scope of inspection

Tank inspection

Weld test(s)

Administer required repairs

Provide evaluation

Types Of Deaerators

Spray type Deaerator System

Spray type deaerator is a cylindrical vessel used for the removal of dissolved gases from the feed water. Basically, the removal of dissolved gases is done by either decreasing the pressure or increasing the temperature inside the deaerator. The feed water fed into the deaerator will pass on through the vented section where the water will experience high steam which allows the feed water to remove dissolved gases. The spray type deaerator diagram is shown below.

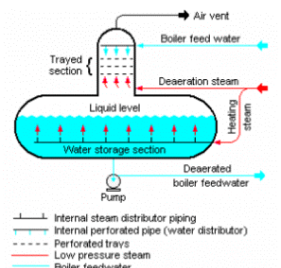

Tray type Deaerator System

Tray type deaerator utilizes a vertical dome placed on the horizontal section of the vessel. The basic difference between a tray-type and spray type is in tray-type both a spray nozzle and trays are used.

By using both spray and trays, the mixing of air and water provides better heat exchange, and the dissolved gases present in the feed water are eliminated more efficiently. The diagram of this deaerator is illustrated below.