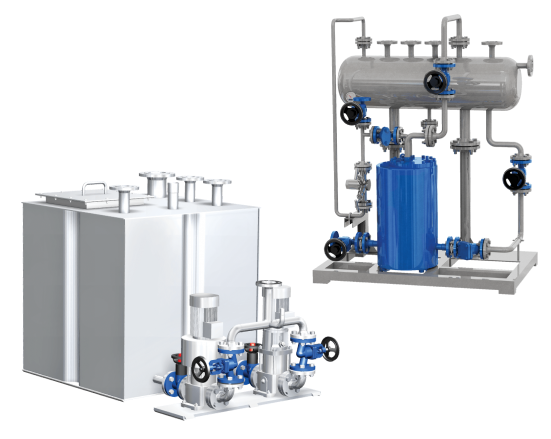

One of the best energy-saving measures for most steam systems is returning condensate to the boiler instead of dumping it to drain. Condensate contains a high percentage of the energy (typically 16 percent) used to produce steam. Recovery and return of all possible condensate back to the boiler plant is the best method for cost containment and improved energy efficiency while providing a safe work environment.