Emergency Service? Call Our 24/7 Line (800) 462-3369

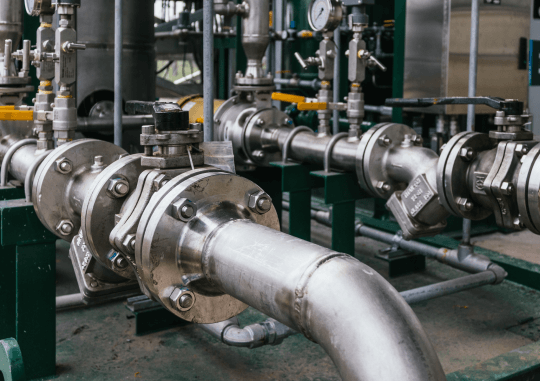

Blowdown Heat Recovery

Systems & Service

ISB’s team of experts will help determine the correct blowdown package that makes the

most economic sense for your company. We will partner with your team to capture

opportunities around flash steam recovery, energy savings, and reduced carbon footprint.

- Recover about 90% of the

blowdown thermal value - Systems offer

a rapid payback

Estimating Savings Opportunities

Values vary depending on volume, boiler pressure, method/frequency of blowdown and fuel cost, but blowdown heat recovery systems can recover up to 90% of the blowdown thermal value.

Blowdown heat recovery system offer a rapid payback in the right conditions, and several boilers can be connected to a single heat recovery unit, reducing capital costs. On average they can achieve payback in under 12 months.

A boiler blowdown heat recovery system

should be considered when:

~ 3-5% of boiler water is make-up

~ 500 lbs/hour of steam is blown down

Continuous blowdown systems

of at least 1 gpm

General formula provided by the

department of energy:

All steam boilers must be blown down to reduce the amount of Total Dissolved Solids (TDS) in the boiler water. However, along with the solids, boiler chemicals and thermal energy is lost; blowdown heat recovery systems cannot recover the chemicals, but they do recover up to 90% of the heat energy that would otherwise be lost down the drain. The recovered heat is used to pre-heat boiler make-up water before it enters the deaerator. This low-pressure steam is used to heat water inside the deaerator, which reduces the cost to run the deaerator and improves overall boiler efficiency.

Reducing the temperature of the blowdown before it reaches the sewer drain is a typical Code requirement. Therefore, a thermal recovery system also eliminates the need to dilute blowdown with cold water before it enters the sewer.